Audit Scope

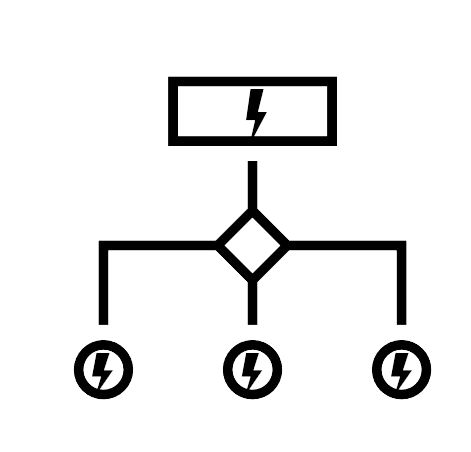

SLD Preparation

A single-line diagram (SLD) is a high-level schematic diagram showing how incoming power is distributed to the equipment.

Read More

Cable Overloading

Conducting load flow studies is an important requirement for the operations. The load flow analysis is an important part of ...

Read More

Short Circuit Studies

Short circuit study is the process of analyzing an electrical system to determine the magnitude of fault currents that flows during

Read More

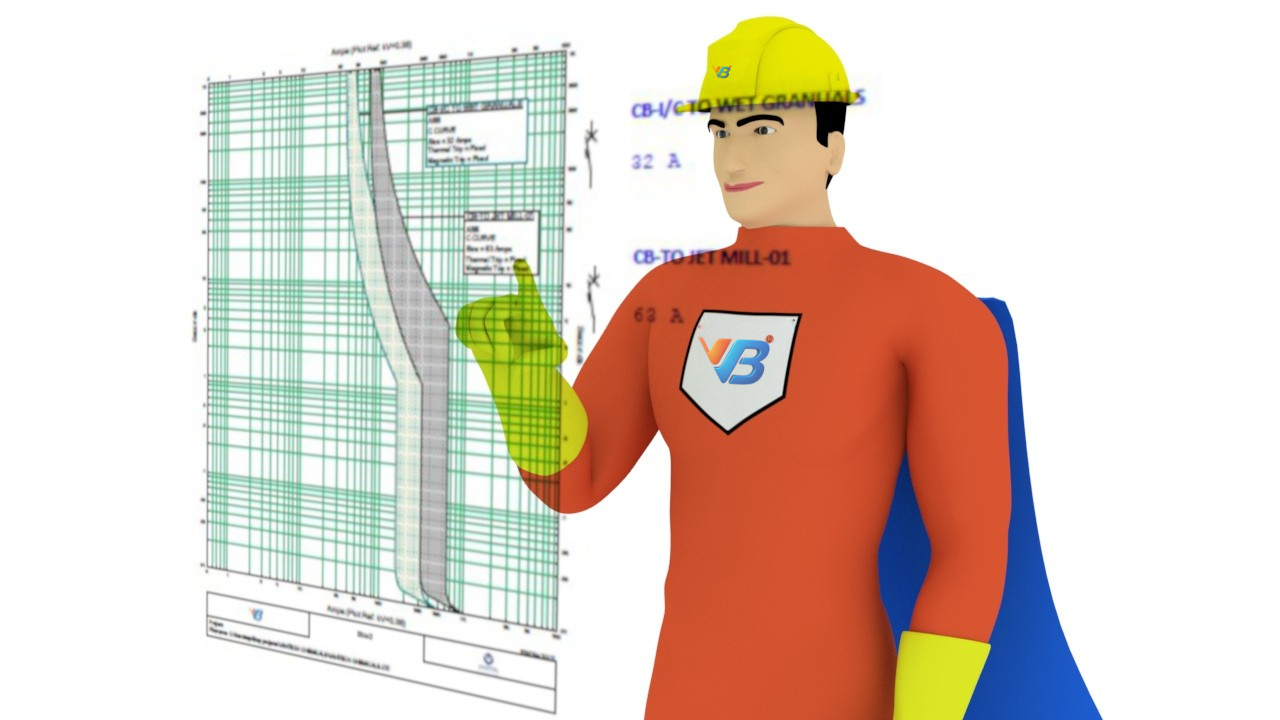

Protective Device Coordination

Protective device coordination is the very important part of design for a electrical network as a part of Power system

Read More

Arc Flash Risk Assessment

VB, is a leader and Arc Flash risk assessment partner for more than 500 global industries. Electrical Arc Flash is an electrical hazard present

Read More

Visual Inspection

Our team will visit the site and visually inspect all the electric hazards and document the details along with images.

Read More

Lightning Arrestor Audit

With the increase in Sensitive electrical equipment's in the workspace, the need for protection against ...

Read More

Earthing Pits Audit

Electrical earthing system design in industries plays a vital role in protecting the equipment...

Read More

Infrared Thermography

"Infrared thermography" is a process which senses infrared energy emitted from equipment...

Read More

Electrical Safety Training

Every once can be a “Safety Hero” . Electrical Hazards awareness and necessary skills to handle the electrical risks is very essential in the work place....

Read MoreA comprehensive electrical audit is a special electrical assessment program developed by the expert and certified electrical auditing team of VB ENGINEERING. Our digitized electrical safety audit enables the customer to identify, analyze, quantify and track the mitigation too.

Onground Verification & Digitization

Our team will visit the site and prepare and conduct a pre audit survey to understand the electrical installations and risk assessment requirements. A comprehensive electrical safety audit model customized for the facility be designed and discussed with the plant team. Our data collection team will visit the plant as per schedule collect the respective data required for various electrical risk assessments which will be a holistic part of electrical safety audit. The data collection team will simultaneously digitise the assets to enable tracking of the audit and mitigation progress. This is a very important step in the process of electrical safety audit as the assets and process digitization plays a vital role in the long run for electrical risk assessment and safety track. The entire electrical safety audit program also will involve people from the plant to ensure the correctness in gap identification and determination of the practically possible solution.

Power System Analysis

The data collected and digitized by our on-site data collection team will be reviewed by our team of engineers to ensure the Quality of data. The data accuracy plays a important role in electrical safety gaps identification so we get the ground data verified thoroughly. The data verified will be submitted to the power system studies team and electrical safety audit team. The data will be prepared for a electrical digital twin model. Our expert power system studies team will perform cables overload assessment, demand load analysis, short circuit analysis, relay coordination studies and protection assessment, Arc Flash risk assessment, safe boundaries calculations, electrical personnel protective equipment determination, Arc Flash boundary calculation, shock boundary calculation, incident energy calculation, lightning protection study, earthpits evaluation infrared thermal inspection and hot spots analysis, visual inspection and hazardous area classification compliance. The detailed electrical safety audit will be performed to identify the gaps.

Standards compliance & Gap Identification

Our Certified Auditors will verify the as is status of the plant incompliance with NEC, NFPA, IEEE, IEC, ANSI, IS, OSHA standars as per applicable. The gaps identified in the electrical safety audit will be documented and results will be tabulated with respect to risk categories for easy understanding of the plant people. The electrical risk mitigation for the gaps and electrical hazards identified during the electrical safety audit will be submitted along with the BOQ to client for immediate action. Detailed electrical safety and risk management training will be conducted to the technicians and other stakeholders. A detailed electrical safety program will be prepared to address the electrical safety requirements as per the standards. Post audit on demand visit will be done by our electrical safety audit team to understand the action taken on the audit report and reevaluate the electrical hazards and assess the electrical risks. Electrical Safety Audit is a scientific way to deal with electrical hazards and assess potential dangers and to prescribe proposals for development of a safe working environment.

ESA is a vital program for identifying electrical hazards, dangers, risks and potential mishaps in an Office, Facility or Plant for deciding essential activity to/limit risks and for guaranteeing that the entire security exertion is viable and significant.

electrical-safety-audit-consultant We at VB Engineering provide a complete range of Electrical safety Audit Services with best reference of standards and guidelines adopted across the world. We perform safety audit based on the electrical safety standards like Nation Fire and Safety Association (NFPA-70E), Occupational Safety and Health Administration (OSHA) and National Electrical Installation (NEC) Standards.

EHS Safety auditing program can be classified into 3 major areas namely:

1. Pre-Audit Survey

2. Audit

3. Post-Audit Survey

Scope of work:

Physical examination to distinguish electrical risks and to recommend

electrical security arrangements

Confirmation of statutory consistence as for Central Electricity Authority and

international electrical safety rules

Survey of plant for lightning protecting adequacy and design

Survey of static electricity and relevant hazards in the plant premises

Work permits, lockout tag out, interlocks audit and verification

Basic electrical safety and behavioral safety in the the organization

Any other required electrical risk assessments as per plant applicability