Engineers use advanced 3D applications to create complex three-dimensional models

that are accurate, complete and unambiguous. These models can be used directly by

CAE (Computer-Aided Engineering) and CAM (Computer-Aided Manufacturing) software to

precisely analyze and manufacture a finished part.

3d Solid Modelling or cad drafting is a main aspect for modern design and development

of products. We can accelerates design and drawings with cad modelling, which saves

time and development costs, and mainly boost productivity with 3D Solid Modelling

capabilities using 3D Design software or 3D drawing preparation and pipe cad.

VB Engineering provides all kind of services like from basic drawing services to the

3D cad drafting services with electrical cad drafting, cad outsourcing and cad

design services etc. It provides the basis for drawing design, simulation, and lean

manufacturing of all parts and we can assemble across the broad range of industries,

applications, and products. 3D solid modelling with speeds the drawing of complex

structures and more large assemblies. Creating 3D solid drafting design of your

project instead of 2D drawings drafting. Please visit our support document, to know

more about 3D cad drafting services or cad design services.

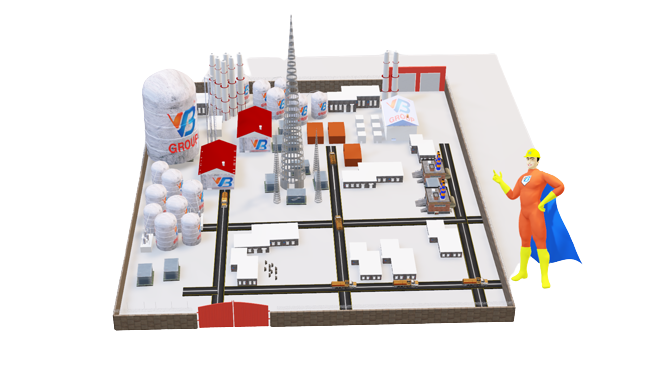

3D CAD Drafting Services and Manufacturing Simulation Software by VB Engineering:

We at VB Engineering provide an expertise 3D CAD Drafting Services or service

globally. The detailed report includes the all CAD drafting details and their ranges

for various parameters. We are also the authorized distributors for Manufacturing

Simulation software product the Flexsim. With unparalleled ease of use and

sophisticated toolpath generation, Edgecam is the only CAD/CAM system you'll need

for milling, turning and mill-turn machining. Edgecam solutions combine the power of

sophisticated toolpath generation with seamless CAD integration. Used globally

within a multitude of industries, Edgecam software consistently produces the best

tool paths to ultimately improve productivity. With unparalleled ease of use and

sophisticated toolpath generation, it is the only CAM system you'll need for

milling, turning and mill-turn machining. Manufacturing simulation lab consists of

using Flexsim Simulation software to build manufacturing models of machines, WIP

stations, warehouses using Racks, ASRS, Robots, AGVs, fork lifts, cranes etc to

create a dynamic factory environment, where students can understand the nature of

manufacturing in 3D and in real time. Flexsim software is mainly used in Advance

Manufacturing Simulation laboratory.

Engineers use advanced 3D applications to create complex three-dimensional models

that are accurate, complete and unambiguous. These models can be used directly by

CAE (Computer-Aided Engineering) and CAM (Computer-Aided Manufacturing) software to

precisely analyze and manufacture a finished part.