Our offerings

S L D Preparation

A single-line diagram (SLD) is a high-level schematic diagram showing how incoming power is distributed to the equipment. It is the blueprint for ...

Read More

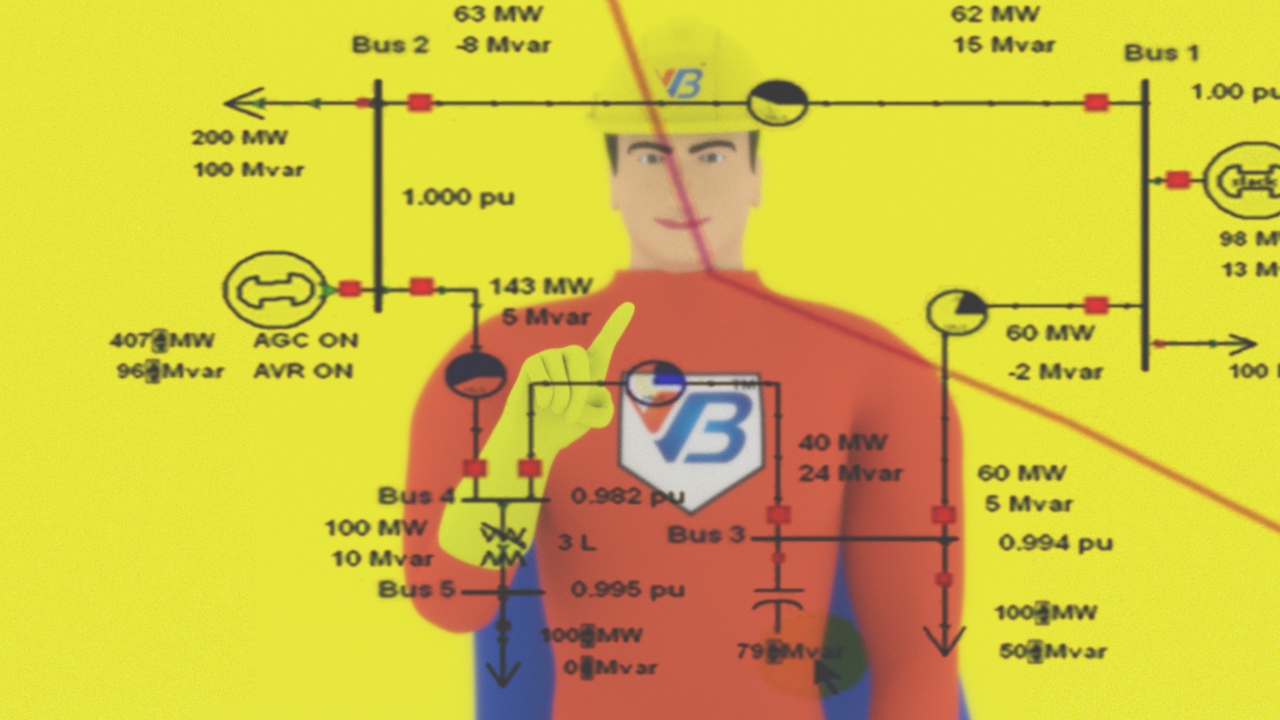

Load Flow Studies

Conducting load flow studies is an important requirement for the operations. The load flow analysis is an important part of the power system ....

Read More

Short Circuit Studies

Short circuit study is the process of analyzing an electrical system to determine the magnitude of fault currents that flows during ...

Read More

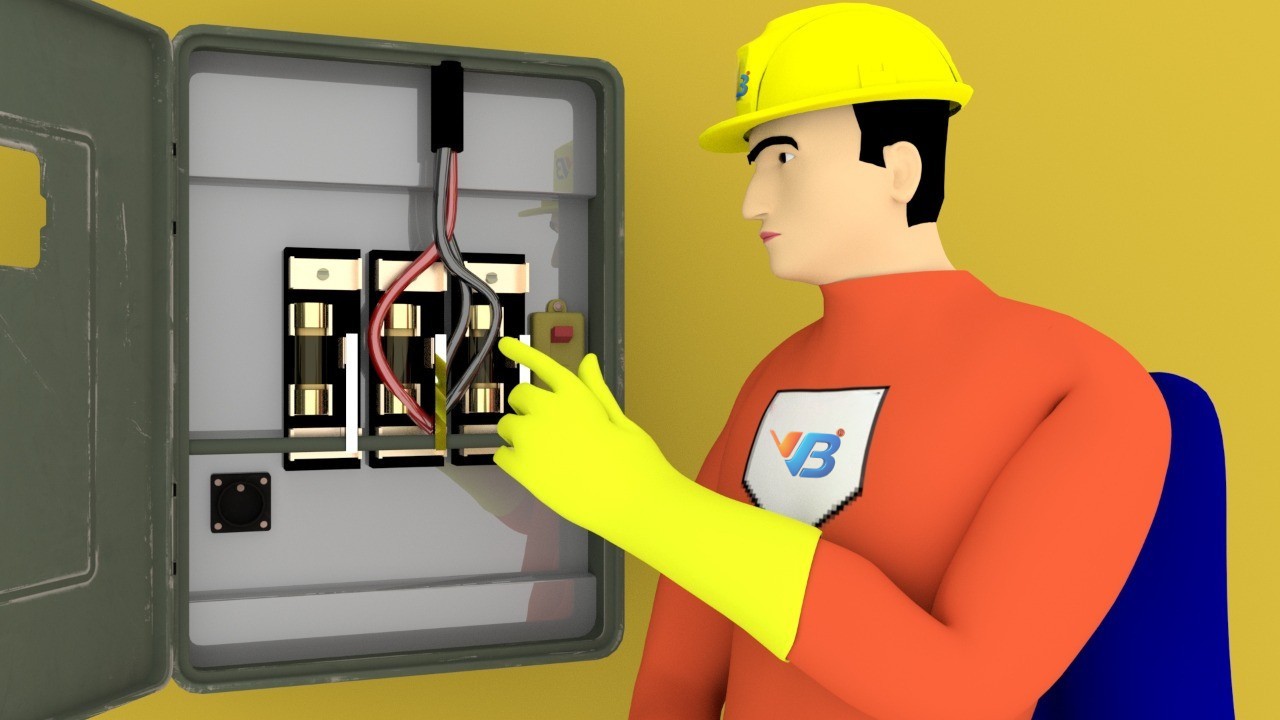

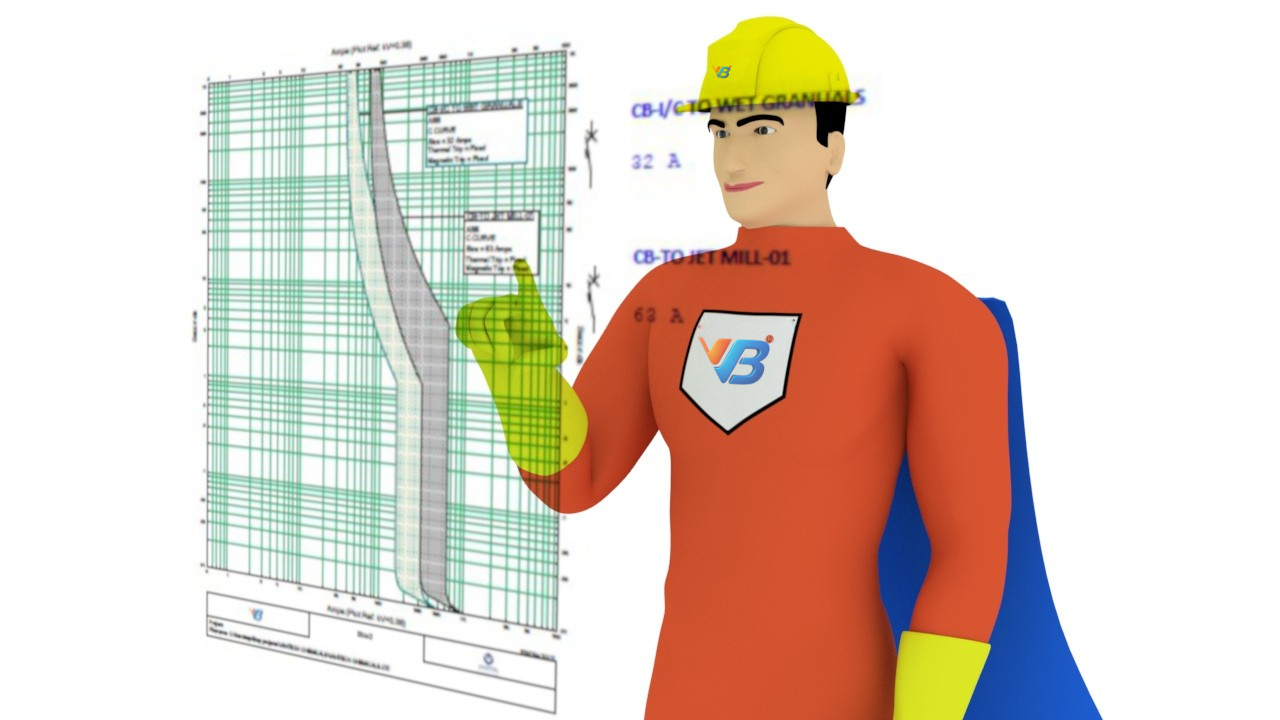

Protective Device Coordination

Protective device coordination is the very important part of design for a electrical network as a part of Power system .....

Read More

Arc Flash Risk Assessment

VB, is a leader and Arc Flash risk assessment partner for more than 500 global industries. Electrical Arc Flash is an electrical hazard present ...

Read More

Harmonic Analysis

Harmonic analysis is the process of identifying the harmonic distortions that occur ...

Read MoreArc Flash Study Standards & Compliance

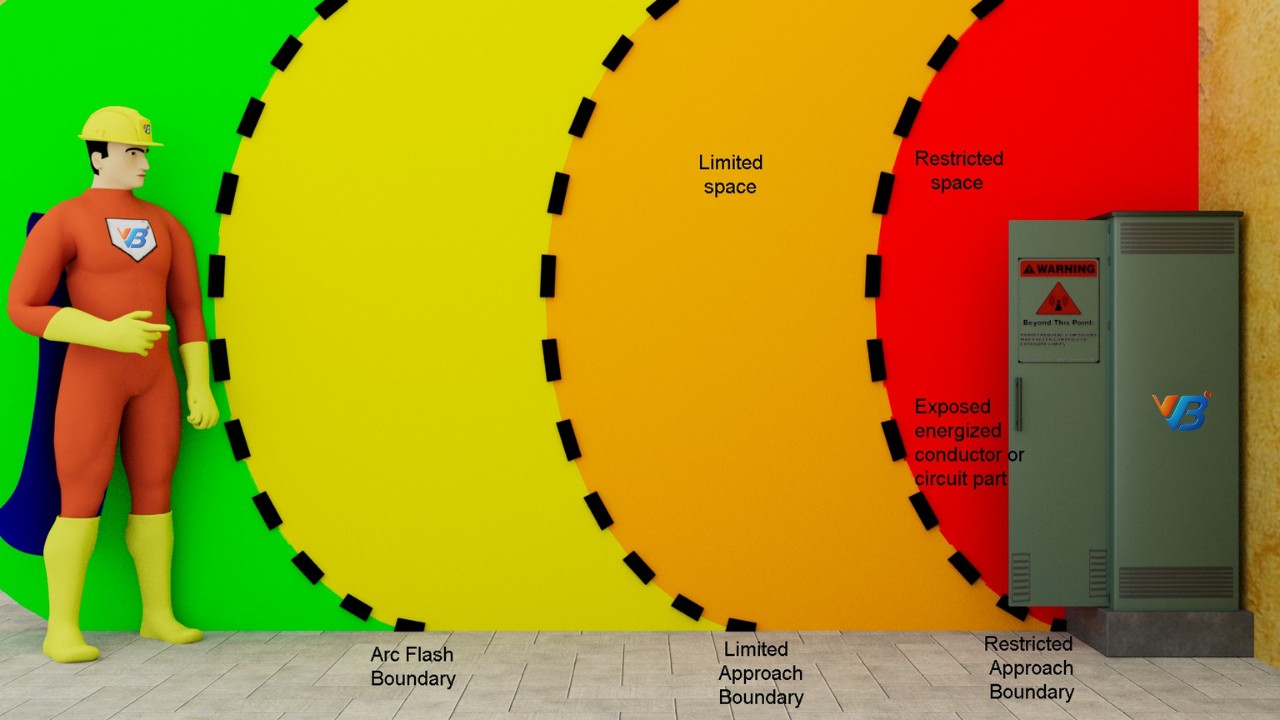

An Arc Flash is associated with high temperatures of about 35000-degree Fahrenheit, Flashing light, releases sound of about 160 DB, and a pressure wave. The metal parts around the conductors melt and vaporize at such high temperatures and sends a blast of molten metal and other metal pieces in all directions causing severe burns and fatal injuries. The Arc Flash Study companies perform Arc Flash study at the facility to reduce the effects caused by Arc Flash and to mitigate the Arc current effectively before it starts a fire. International Standards like OSHA, NFPA 70 E, IEEE 1584-2018, IEC, provide guidelines and modelling methods to determine Arc Flash hazard and to provide safe working conditions. Australian government has formulated certain standards to meet any flaws of the international standards and the electrical requirements in Australia. Some of them are ENA(Energy Networks Association), AEC(Australian Energy Council), AS3000:2018. The major role of these standards organizations is to supervise and maintain safe operating conditions and minimize Arc Flash Hazards.

Planning to Conduct Arc Flash Analysis?

Arc Flash Hazards & Mitigations

Electricity is a source of energy which has its share of dangers. And a cautious operation is always the best practice of working on energised lines and live equipment.Electric shocks are the widely acknowledged electric hazards. Arc Flash, Electric shock, Electric faults, short circuits, lightning strikes are the main Electrical accidents that are common to any facility irrespective of the size and operating voltages. It is our practice of employing latest software like ETAP, Easy Power, SKM, TANTRA in modelling of your facility and there by understand the predicament of Arc Flash at your facility in a systematic way. One Line Diagrams are developed by the current software with consideration of all the available data at the facility. One line diagrams illustrated by our Arc Flash study company are easy to understand and always pose a possibility for expansion for future purpose. Empirical modelling of your facility with quick response from our team ensures you fast responses for the Arc mitigation making your facility more flexible and reliable during operation. Thousands of buses can be compared and analysed and a quick response is attained.

Detailed Engineering Services

Our other engineering services may also help you

3D Factory Animation

We Build, Create and Animate the 3D models of the plants. Feel the Amazing 3D Walk Through of Your Plant. Its very simple. Let us know your ....

Read MoreS L D Preparation

A single-line diagram (SLD) is a high-level schematic diagram showing how incoming power is distributed to the equipment....

Read MoreShort Circuit Studies

Short circuit study is the process of analyzing an electrical system to determine the magnitude of fault currents that flows during ...

Read MoreProtective Device Coordination

Protective device coordination is the very important part of design for a electrical network as a part of Power system .....

Read MoreArc Flash Risk Assessment

VB, is a leader and Arc Flash risk assessment partner for more than 500 global industries. Electrical Arc Flash is an electrical ...

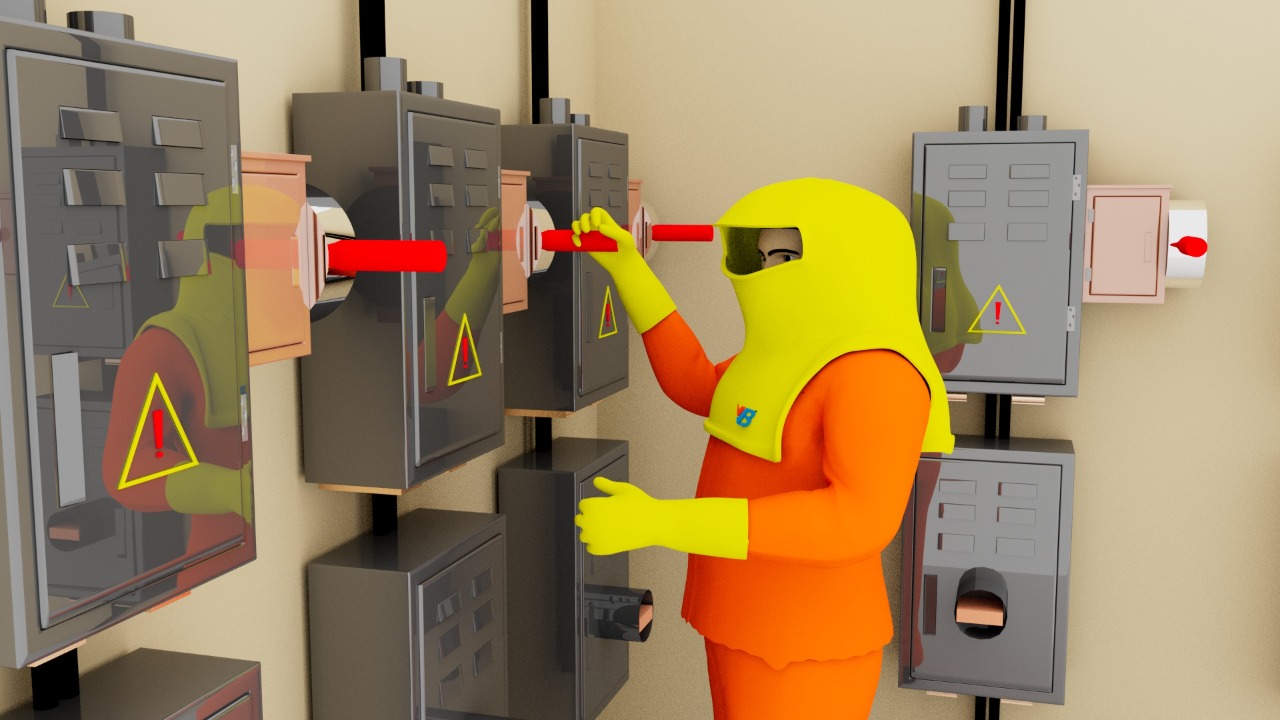

Read MoreArc Flash PPE

Arc Flash PPE is Arc rated personal protective equipment worn by workers performing maintenance on energized equipment ....

Read MoreHarmonic Analysis

Harmonic analysis is the process of identifying the harmonic distortions that occur in the electrical distribution system. VB provides turnkey ...

Read MoreLoad Flow Analysis for Oil and Gas

Conducting load flow studies is an important requirement for the operations. The load flow analysis is an important part of the power system ....

Read More2D CAD Drawings

2D drawing is a drawing that represents in only in X and Y-axis. More simply, a 2D drawing is flat and has a width but no depth or thickness.

Read More3D Isometric Manufacturing Drawings

3D or Isometric drawings means showing an object in 3axis (X, Y &Z) result in the replication of the exact designed product after manufacturing.

Read MoreFire Escape Floor Plan Drawings

Fire Escape Floor plan is one of the foremost providers of CAD services forget the people provide security and safety during working.

Read MoreP&ID Designing and Drafting

Piping and instrumentation drawing or P&ID Drawing is used to describe the total engineering process like from the source (Machine/Equipment) to ...

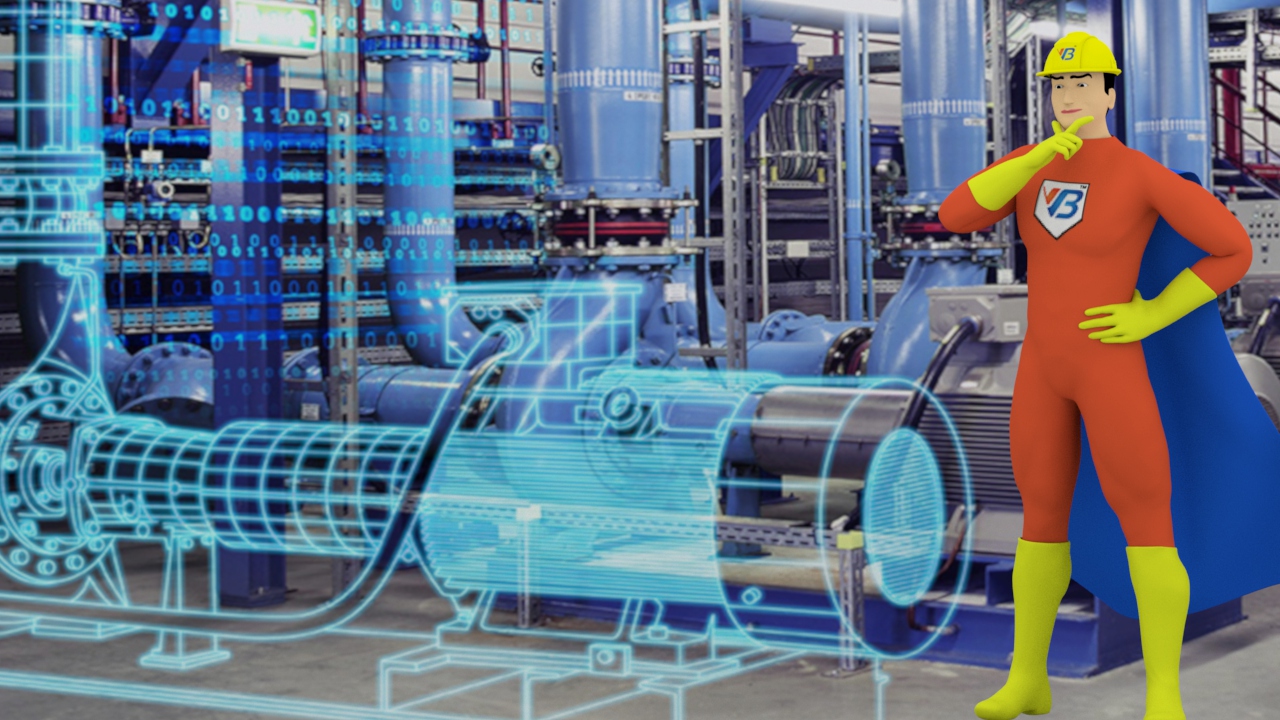

Read MoreReverse-Engineering

Reverse engineering is the process of discovering the technological principles of a device, object or system through analysis of its structure ...

Read MoreLean Simulation

A simulation methodology followed by the world class manufacturing units. Lean manufacturing has been a best practice across the globe in manufacturing process.

Read More3D Plant Simulation

Planning, designing and modelling of a system by simulation before the real time implementation is the present-day trend.

Read MoreARC Flash Study Analysis

Arc Flash labels are clear and easy to understand specifying the need of PPE, operating distance, incident energy, Arc fault current available, HRC, Appropriate PPE in accordance to the local and international standards. The Arc Flash labels are computer modelled and provide you with right labelling for the required operation. Arc Flash study cost with VB Engineering proves to be very effective with the RIGHT suggestions suiting your business needs and to meet your quest in providing safer work place conditions for the working personnel. The Arc Flash Study cost is justified with the advantages Arc Flash Hazard analysis has to offer. The periodical Arc Flash Study at the facility and the records of the Arc Flash Study reports turns away the event of being fined by the local laws and international standards, hospital expenses to be met are averted, loss in production due to an outage caused by an Arc Flash, need of new equipment that are expensive and have been damaged during Arc Fault can be totally avoided and thus saving millions of Dollars. And as such the Arc Flash Study Cost is an investment benefitting the business.

Most recent Arc Flash incidents observed in Western Australia, Perth and other locations indicate that an Arc Flash Incident can occur at any facility like commercial, residential, industrial points. Some of the causes that are observed to be causing Arc Flash Hazard are listed below:

Human error: This is the case of an error in majority Arc Flash hazards like in the cases of the operating personnel dropping tools, being non vigilant while opening or closing contacts, negligence in following the Arc Flash Hazard analysis guidelines, ignorance of the high risk working environment, non-compliance of the standards provided by safety organizations.

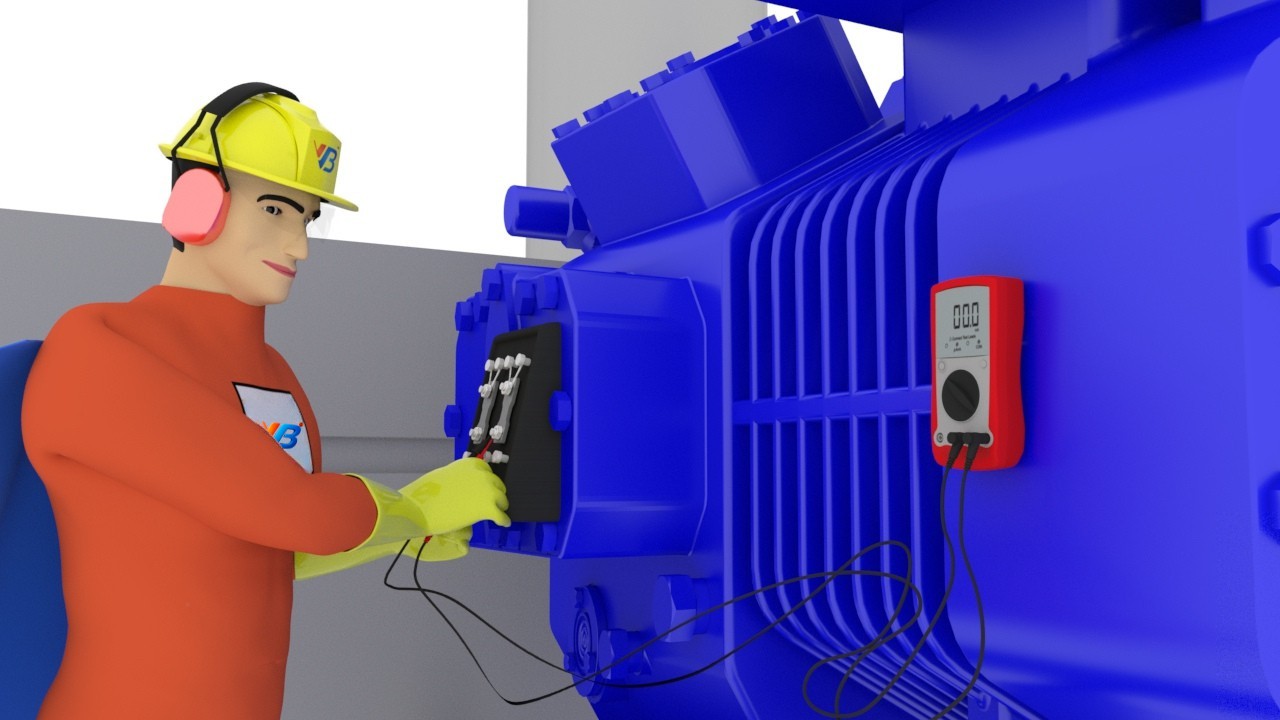

Low maintenance: Periodic check on the equipment helps in identifying any damage, making sure that the circuit breakers, fuses are in working conditions and are not prone to wear and tear. Damage in circuit breakers, other protective devices. Moisture

Dust and debris accumulation

Rodent infestation, cob webs and other small animals making it a conductive path for the Arc

current.

Poor design. Inadequate Ratings of fuses and other circuit breakers, digital meters connected in the

circuit, employing poor quality equipment.

Erroneous connections and installations

Arc Flash study helps to identify these causes of Arc Flash, Analyse which type of equipment is at risk of an Arc Flash, methods to mitigate the Arc, suggest required PPE for the Arc Flash calculation performed at the facility. Arc Flash Study cost with VB Engineering is in accordance with the company's expectations and the size of the facility. Arc Flash Analysis with VB Engineering includes a detailed load flow study, short circuit coordination study, harmonics, contingency analysis meeting the Arc Flash study requirements.

Arc Flash Hazard Solutions and Report

Data Acquisition: All the data of the system up-to-date from the company records and a field survey by our team of experts is collected and analysed, formulate the causes that may result in an Arc Flash.

Modelling the data : At VB Engineering we employ standard tools like ETAP(Electrical Transient Analysis Program), SKM, Easy Power, TANTRA that are helpful in analysing thousands of buses at a go. Single Line Diagrams showing all the connections, ratings, transformer, tap changers, fuses, circuit breakers, MCC (Motor Control Centre) s, X/R ratios, power angle, Transformer sizes, types of phases, grounding types are depicted and modelled to determine possibilities of Arc Flash , methods to reduce the effects of Arc Flash Hazard.

Arc Flash Hazard Analysis: Our skilled Engineers propose operating practices that act in alternative practices to create awareness in the working personnel about the Arc Flash through our systematic and elaborate Arc Flash Hazard Analysis. At VB Engineering in accordance with the IEEE 1584-2018, and Australian standards for the Arc Flash calculation are employed. Arc Flash Calculation is MAINLY the determination of the Arc Fault current, Bolted Fault Current (3- phase symmetrical fault current), IE (Incident energy) Amount of Incident energy the working personnel is exposed and methods of reducing the amount of incident energy with short circuit coordination study.

Short circuit coordination study: Based on the mathematical models developed, the normalized incident energy for the different modes of operation of the electrical system and the different configurations of the conductors, air gaps between the conductors, cable sizes, types of phases in the system HRC categorized. The time taken for the interruption of short circuit. The TCC (Time Current Curves) provide the necessary data for the short circuit coordination study and the protective device coordination. The main avidity of the Flash hazard analysis is to prevent the Arc Flash occurrence at a very early stage. This is made possible with devices called as Arc Fault Circuit Interrupters. Unlike circuit breakers that are most widely employed for protection, Arc Fault Circuit Interrupters identify the electric Arc current that may flow in unintended path and opening the circuit before it continues to be further energised causing an Arc Flash and fire. With short circuit coordination study reports our team of experts suggest modifying or employing new settings for a coordinated operation of protective devices based on the overlapping of the TCC of the protective devices and switch gear assemblies.

Arc Flash Study Report: Based on the Arc Flash Survey at the facility, VB Engineering formulates a detailed Arc Flash Study Report. The objective of the Arc Flash Survey is to perform Flash hazard analysis meeting with the Arc Flash requirements and to provide a safe working environment for the employees. Arc Flash Study Report further provides with Arc Flash labelling in compliance with OSHA, NFPA 70 E, NEC, AEC, ENA standards. We provide the necessary Arc Flash Hazard training to the employees in identifying the Arc Flash Hazard environment, read and understand Arc Flash Hazard labels and there by choose right working practices and appropriate PPE and Arc Flash Approach boundaries. With regards to Electrical safety at your workplace Arc Flash study helps you to avert the adverse effects caused during an Arc Flash. Consult our Arc Flash Study consultant for a cost effective and expert advice.

VB Engineering facilitates you to get an Arc Flash Analysis complying with the state and international standards. Choosing the right Arc Flash company for your facility is a pivotal decision. VB Engineering is a leading Arc Flash Study company with a team of expert Arc Flash Hazard analysis professionals guiding many businesses in performing an Arc Flash study and mitigate Arc Flash hazard. With vast experience as our tenacity, we provide most accurate solutions and methods compatible with the design and functioning of your facility.

Arc Flash is seen from the statistics to be more prone to causing fatal injuries, injuries with severe burns, damage to eyesight, ears and hearing ability, breathing problems. Safe work practices are always the best protection. When a fault current flows in a low resistance path it leads to an Arc Flash. The fault current when attains a sufficient energy, results in ionizing the air surrounding the conductors leading to a blast called as Arc blast or Arc Flash.