Our offerings

S L D Preparation

A single-line diagram (SLD) is a high-level schematic diagram showing how incoming power is distributed to the equipment. It is the blueprint for ...

Read More

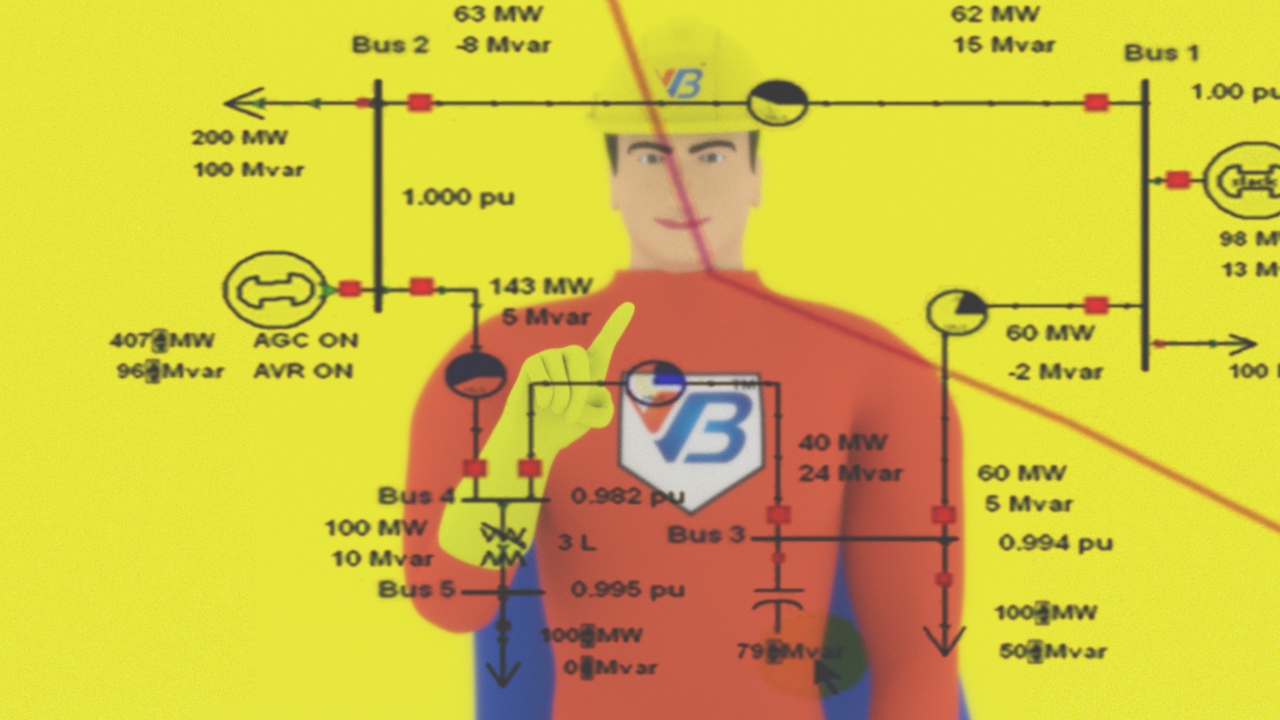

Load Flow Studies

Conducting load flow studies is an important requirement for the operations. The load flow analysis is an important part of the power system ....

Read More

Short Circuit Studies

Short circuit study is the process of analyzing an electrical system to determine the magnitude of fault currents that flows during ...

Read More

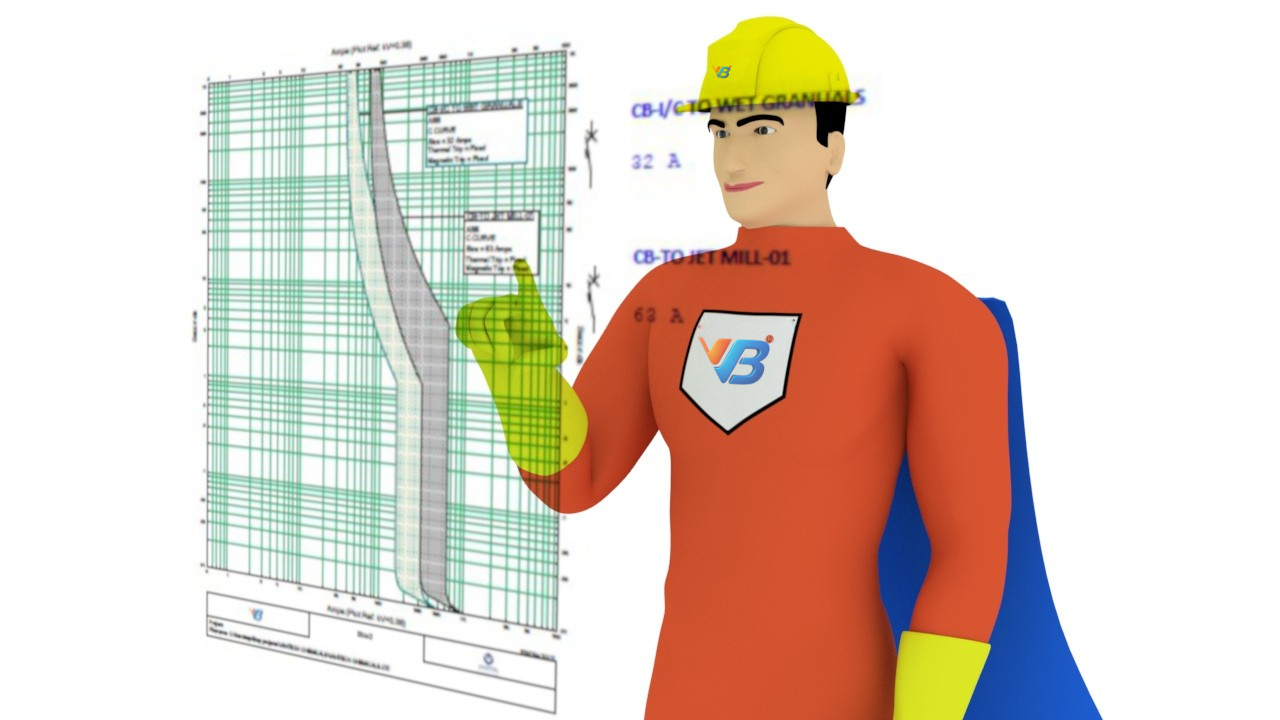

Protective Device Coordination

Protective device coordination is the very important part of design for a electrical network as a part of Power system .....

Read More

Arc Flash Risk Assessment

VB, is a leader and Arc Flash risk assessment partner for more than 500 global industries. Electrical Arc Flash is an electrical hazard present ...

Read More

Harmonic Analysis

Harmonic analysis is the process of identifying the harmonic distortions that occur ...

Read MoreArc Flash Study Standards & Compliance instead

VB Engineering in its vast experience in Arc Flash studies and Arc Flash Hazard Analysis and with the up-to- date statistics of Arc Flash incidents world wide found that many of the Arc Flash incidents could have been prevented with improved and employing healthy operating practices and a periodic Arc Flash study conducted at the facility. Also, the standard regulations proposed by OSHA, NFPA 70 E, IEEE 1584- 2018 recommend a periodic Arc Flash Survey at the facility, get Arc Flash Hazard Analysis for every 30 % change in the load and maintain a record of the Arc Flash Study Reports that are conducted at the facility periodically.

Planning to Conduct Arc Flash Analysis?

Arc Flash Hazards & Mitigations

As per the guidelines of OSHA, NFPA, IEEE- 1584 periodic Arc Flash survey is mandatory at every business, industry and commercial facilities. With possible changes in the load by 30 % an Arc Flash hazard analysis is the BEST way in meeting up with the requirements of safety of the working personnel. Arc Flash study cost expended at your facility paves to be an intellectual measure for the management as it helps in mitigating Arc Flash incidents, hospital bills to be met up, insurance claims, possible shutdown of the facility effecting the production and causing millions of pounds loss to the firm. Arc Flash hazard analysis identifies the possible Arc Flash hazard causing equipment and suggests guidelines in redesigning the existing system in an effective way, point out several operating practices so as to avoid Arc Flash, identify the Arc Flash hazard operating conditions and selection of the appropriate PPE for the job to be accomplished.

Detailed Engineering Services

Our other engineering services may also help you

3D Factory Animation

We Build, Create and Animate the 3D models of the plants. Feel the Amazing 3D Walk Through of Your Plant. Its very simple. Let us know your ....

Read MoreS L D Preparation

A single-line diagram (SLD) is a high-level schematic diagram showing how incoming power is distributed to the equipment....

Read MoreShort Circuit Studies

Short circuit study is the process of analyzing an electrical system to determine the magnitude of fault currents that flows during ...

Read MoreProtective Device Coordination

Protective device coordination is the very important part of design for a electrical network as a part of Power system .....

Read MoreArc Flash Risk Assessment

VB, is a leader and Arc Flash risk assessment partner for more than 500 global industries. Electrical Arc Flash is an electrical ...

Read MoreArc Flash PPE

Arc Flash PPE is Arc rated personal protective equipment worn by workers performing maintenance on energized equipment ....

Read MoreHarmonic Analysis

Harmonic analysis is the process of identifying the harmonic distortions that occur in the electrical distribution system. VB provides turnkey ...

Read MoreLoad Flow Analysis for Oil and Gas

Conducting load flow studies is an important requirement for the operations. The load flow analysis is an important part of the power system ....

Read More2D CAD Drawings

2D drawing is a drawing that represents in only in X and Y-axis. More simply, a 2D drawing is flat and has a width but no depth or thickness.

Read More3D Isometric Manufacturing Drawings

3D or Isometric drawings means showing an object in 3axis (X, Y &Z) result in the replication of the exact designed product after manufacturing.

Read MoreFire Escape Floor Plan Drawings

Fire Escape Floor plan is one of the foremost providers of CAD services forget the people provide security and safety during working.

Read MoreP&ID Designing and Drafting

Piping and instrumentation drawing or P&ID Drawing is used to describe the total engineering process like from the source (Machine/Equipment) to ...

Read MoreReverse-Engineering

Reverse engineering is the process of discovering the technological principles of a device, object or system through analysis of its structure ...

Read MoreLean Simulation

A simulation methodology followed by the world class manufacturing units. Lean manufacturing has been a best practice across the globe in manufacturing process.

Read More3D Plant Simulation

Planning, designing and modelling of a system by simulation before the real time implementation is the present-day trend.

Read MoreArc Flash Study Analysis

An Arc Flash is associated with 160 DB sound causing acoustic problems, Flash of the light causing temporary or permanent blindness in the operating personnel. And an explosion of such magnitude occurring in an oil, gas or a chemical industry can lead to a chain of other malignant explosions and damage to the equipment, causing fatal injuries to the workers in the vicinity. And a country like Egypt with a major industries like oil and petroleum, agriculture, chemical manufacturers opt or a higher priority to the safe working environment. Apart from the blunders on part of the operating personnel other causes of Arc Flash include

Dust accumulation (by proper maintenance) Moisture

Infestation caused by rodents and other animals Creeping currents

Protective relays and circuit breaker failures. Damage of switch gear

Breakdown of insulation causing sparks at the broken insulation.

Working on energised lines.

Exposed live parts.

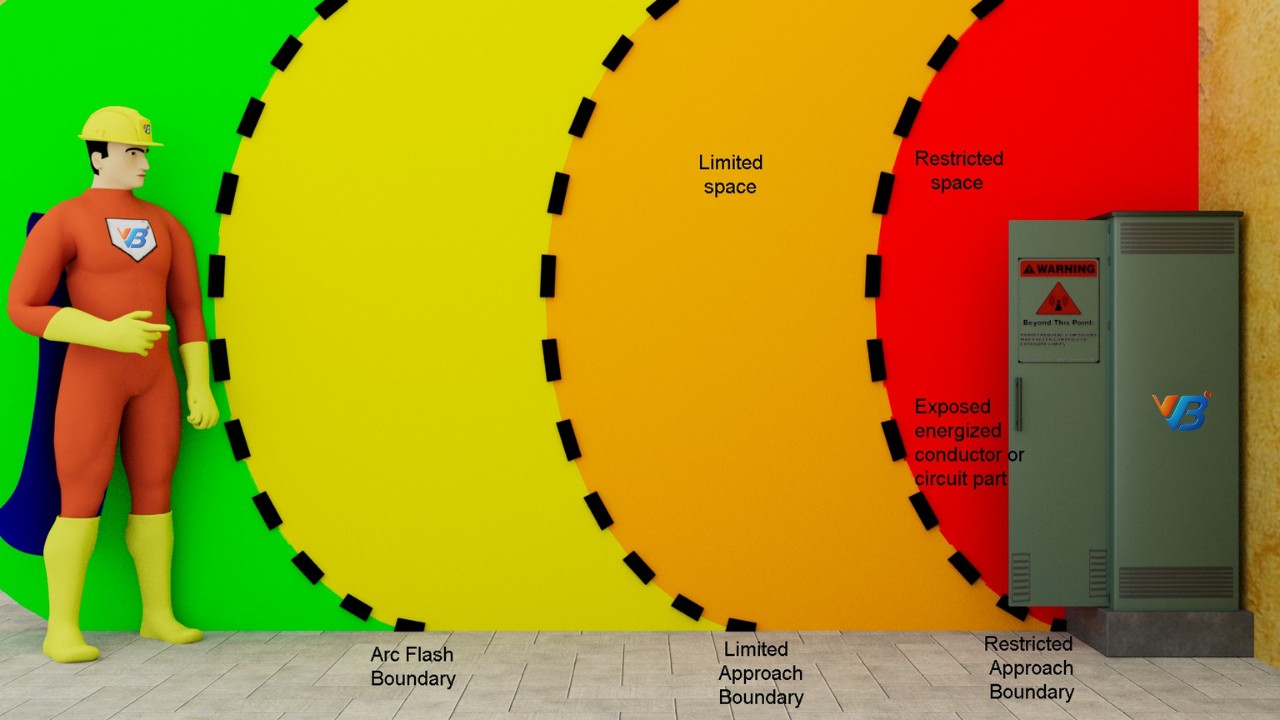

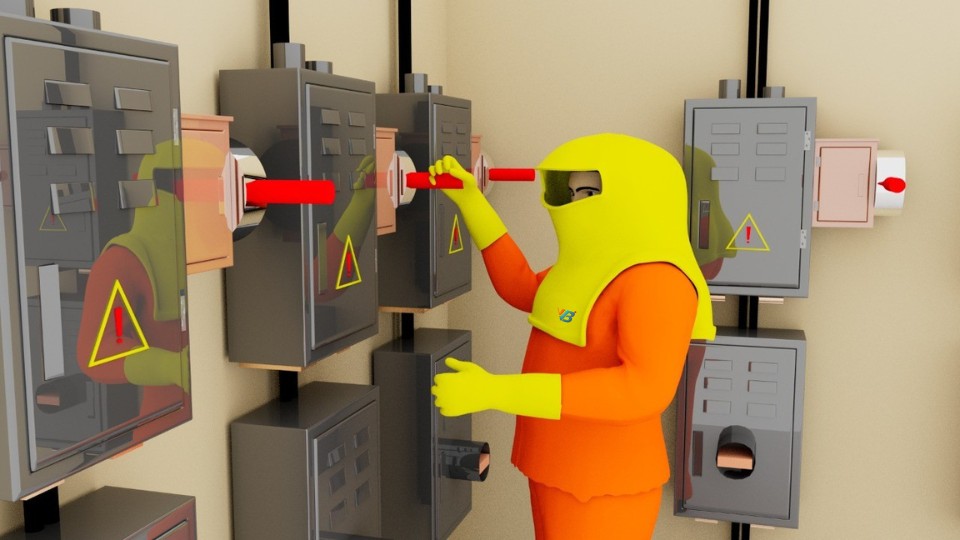

Arc Flash is an unintended phenomenon which has drastic effects. Injuries leading to death or fatal incidents are reported in Arc Flash incidents. A fault such as ground fault, line to ground fault or a short circuit can cause an Arc Flash. The fault current when not mitigated in time may follow an unintended path between the conductors and ionising the air surrounding it. Arc Flash is characterized with high temperatures of about 35000-degree Fahrenheit which is around 5 times the temperature of the sun. Heat caused during the Arc Flash causes the air to vaporise and melting the metal parts like the conductors and causes a blast of molten metal, plasma shrapnel in all directions with a high pressure. An Arc Flash is associated with 160 DB sound causing acoustic problems, Flash of the light causing temporary or permanent blindness in the operating personnel. And an explosion of such magnitude occurring in an oil, gas or a chemical industry can lead to a chain of other malignant explosions and damage to the equipment, causing fatal injuries to the workers in the vicinity. And a country like Egypt with a major industries like oil and petroleum, agriculture, chemical manufacturers opt or a higher priority to the safe working environment.

Listed below are the methods of Arc Flash mitigation:

Regular maintenance of the equipment so as to get rid of accumulation of dust and dirt. Employ right operating practices. Like permitting only the qualified employees for the necessary operations. Training the employees on the risk of Arc Flash Hazard and to identify the Arc Flash hazard labelling. Be vigilant while working on live parts, maintaining the appropriate Arc Flash Boundaries, practicing appropriate PPE for different categories of incident energy. Keeping the tools in order and secured properly so as to avoid the risk of Arc Flash occurring due to dropping of tools. Proper check on the clamps, and contacts so as to ensure their proper operation. This is necessary as the contacts and breakers are operated only under fault conditions. Check regularly for any insulation failure at the cables and take appropriate measures. Employ proper enclosure types for the conductors to achieve protection from different weather conditions. This benefits in avoiding the moisture around the conductors. Arc Flash Study at the facility identifies other causes of Arc Flash possibilities and Arc Flash risk assessment at different equipment. Arc Flash study with a well-versed Arc Flash company ensures right measures with effective Arc Flash study cost. Periodic check on circuit breakers and other protective devices. Many a times it takes a professional to identify the issue with these devices. Hence an Arc Flash Study from an Arc Flash study company is highly recommended. De-energizing the lines while working on them. NFPA 70 E directs that it is mandatory to de-energize the lines while working on them. Also, NFPA 70 E has proposed several practical scenarios where an exemption can be made and to work on live circuits for testing and trouble shooting. But in many practical scenarios, the production is compromised as de-energizing leads to interruption in production that in some cases may cause a huge loss in hundreds of pounds. A lot of Arc Flash companies avail the Arc Flash study. Choosing the right company is a prominent decision in safe guarding the facility.

Arc Flash Hazard Solutions and Report

Data collection, Field verification and acquire the necessary information of sources and loads, generators, feeders, capacitor banks, circuit breakers, protective relays, types of connections, tap changers, KVA/MVA ratings, fuses, types of grounding employed on site. Our expert team of engineers identify the possible devices that may cause the risk of Arc Flash, new devices to be employed by replacing old, worn out or erotic devices, idle devices that are placed at points where they are not needed. Develop Electrical drawings if necessary. Single line diagrams depicting all the equipment, loads, connection, buses, loads, circuit breakers, ratings, operating times, name plate details. With SKM Power tools, ETAP, TANTRA and other software, VB Engineering presents you with a detailed SLD identifying the possible Arc Flash Risk causing equipment, need of Arc Flash Hazard labelling.

Arc Flash calculation. IEEE 1584-2018 put forward with formulae and mathematical models in calculating short circuit currents, Arc fault currents, bolted fault currents, incident energy, that are implemented in determining Arc Flash Hazard Analysis. Many a practical scenarios like horizontal and vertical alignment of the conductors, types of enclosures, gap between the conductors that play an important role Arc Flash hazard assessment. With power tools like SKM, short circuit currents, RMS values, Impedences, X/R ratios of all equipment operating above 230V, creeping currents, branch currents that energise the Arc under fault conditions are evaluated in Arc Flash Evaluation implementing the mathematical models in IEEE 1584 -2018.

Arc Flash Hazard assessment. The values obtained from the Arc Flash Calculation PROVIDE the incident energy, normalised incident energy, distance of operation available fault currents, bolted fault currents help in the Arc Flash Hazard assessment. At each individual equipment that has been identified at a risk of an Arc Flash in the field survey by the engineers the Arc Flash hazard assessment is exacted in compliance to the Arc Flash study requirements. On achieving the Arc Flash hazard assessment at each equipment the Arc Flash Hazard Risk Categories are determined followed by identifying the Arc Flash boundaries.

Short Circuit Coordination Study

Short circuit coordination study. From the SLD and the data acquired through Arc Flash Calculations, the short circuit coordination study is realised. With SKM coordination study hundreds and thousands of buses are analysed at a time. SKM coordination study provides TCC curves of protective devices, and operating times and delay times of other protective devices, circuit breakers is evaluated. Short circuit coordination study provide the operating characteristics of different protective devices, and suggest the necessary settings for mitigation of Arc Flash. Circuit breakers with integral units help to identify which circuit breakers are to be opened such as the upstream or the downstream protective equipment. Short circuit coordination study thus, enables the system to identify different Arc mitigation methods.

Is safety of your workers the highest priority of your facility? Then VB Engineering offers its services in Arc Flash Study, Arc Flash Hazard Analysis, Arc Flash Calculation and short circuit coordination studies hailing from a satisfied clientele globally with a varied range of industries commercial, industrial, domestic, transmission and distribution, manufacturing industries and the like. VB Engineering is a pioneer with expert engineering professional and analysts among Arc Flash study companies. Arc Flash study Companies provide Arc Flash Study report at your facility with Arc Flash Study calculations, Arc Flash hazard Analysis. In performing the Arc Flash study, Arc Flash study companies are to comply with the international safety standards proposed by OSHA, NFPA 70 E, IEEE 1584-2018, NEC and other regulatory bodies executed by the Egyptian law for the electrical and fire safety for the workers. There is no substitute for expert, professional recommendations that we at VB Engineering provide in the Arc Flash Study Report complying with OSHA, NFPA, IEEE, NEC regulations. The choice of the right Arc Flash study company is the initial step in safeguarding your facility from Arc Flash hazard.

Arc Flash Study Report formulation

Report preparation. A detailed Arc Flash Study Report is established considering all

the calculations, short circuit coordination study report, HRC along with necessary steps to be

implemented at the facility such as Arc Flash Hazard labelling, Training the working personnel on

the Arc Flash risk and opting the required PPE for the job, necessary measures to be taken in the

event of an Arc Flash. The report helps in taking the necessary measures and make your facility safe

for the working personnel. OSHA, NEC, NFPA IEEE 1584 - 2018 suggest the Arc Flash study reports and

tabulation of the evaluations to be maintained. Arc Flash study report further helps in future Arc

Flash Hazard Analysis.

There is no substitute for technical procedures and survey. Contact our consultant for Arc Flash

Study at your facility.