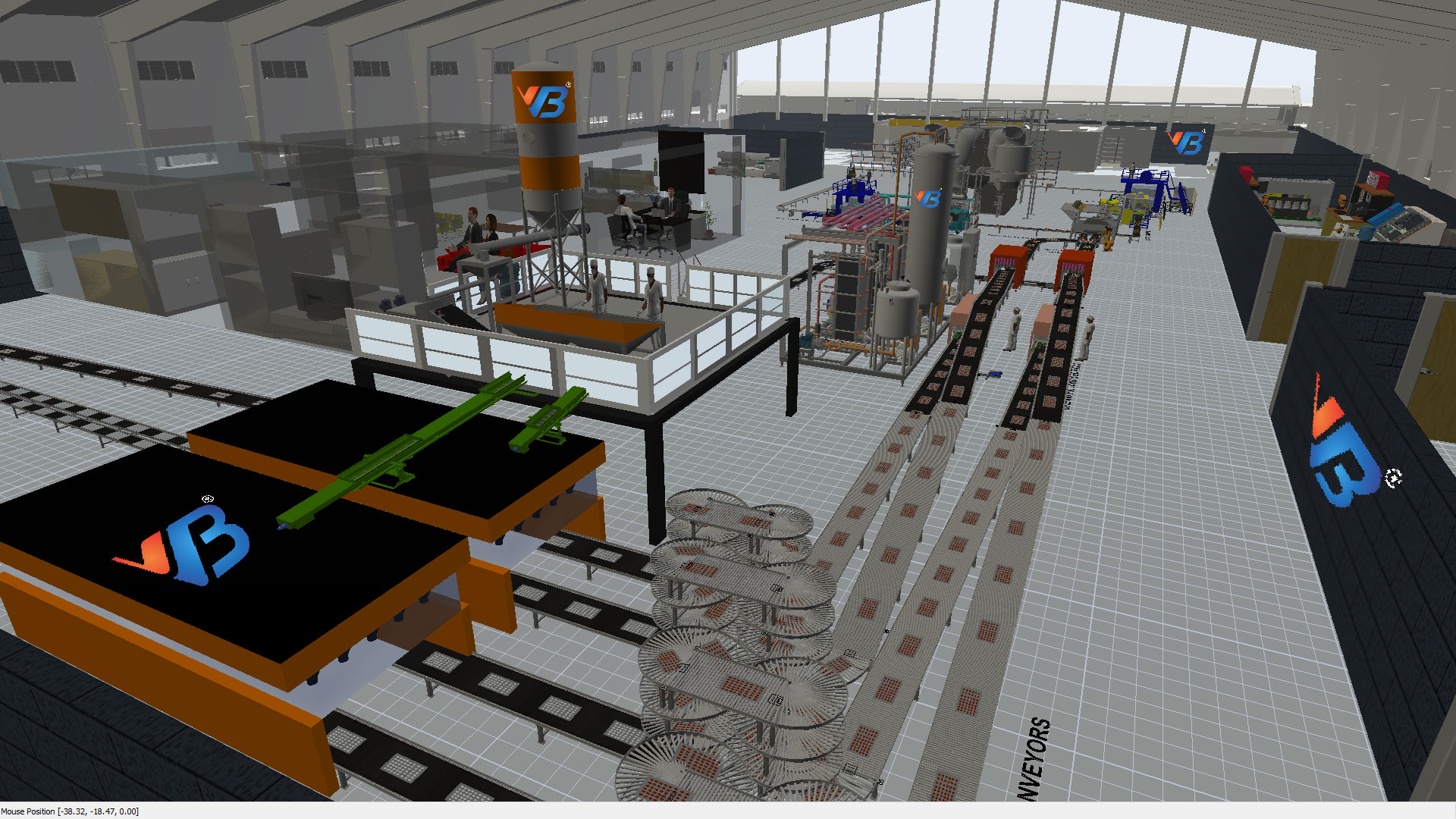

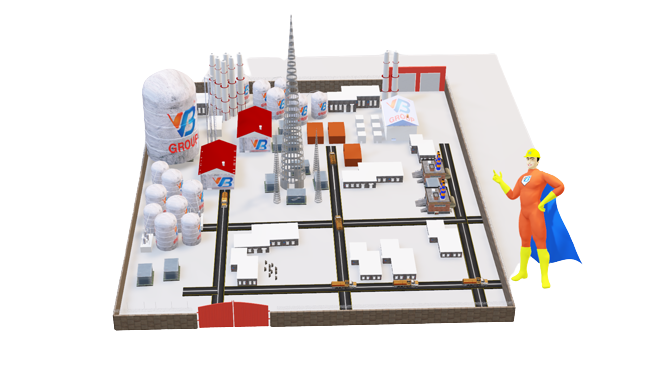

Optimal Floor Planning Introduction:

An optimal floor plan is one that maximises the functionality, efficiency, and comfort of a space. It should consider the purpose, size, shape, and orientation of the space, as well as the needs and preferences of the users. An optimal floor plan should also allow for natural light, ventilation, and circulation, as well as accessibility and safety. Moreover, an optimal floor plan should be flexible and adaptable, so that it can accommodate future changes and modifications without compromising the quality and performance of the space. An optimal floor plan is not only a technical solution but also a creative expression of the users’ vision and values.

Any factory or plant can perform one, two or perhaps three of below Key Manufacturing Tasks superbly but it can do more rare ocations. A factory or plant layout is an engineered design and, like any engineered design it optimizes performance on any dimensions while sacrificing performance on anothers. It must because of technical limitations in the facility.

Features

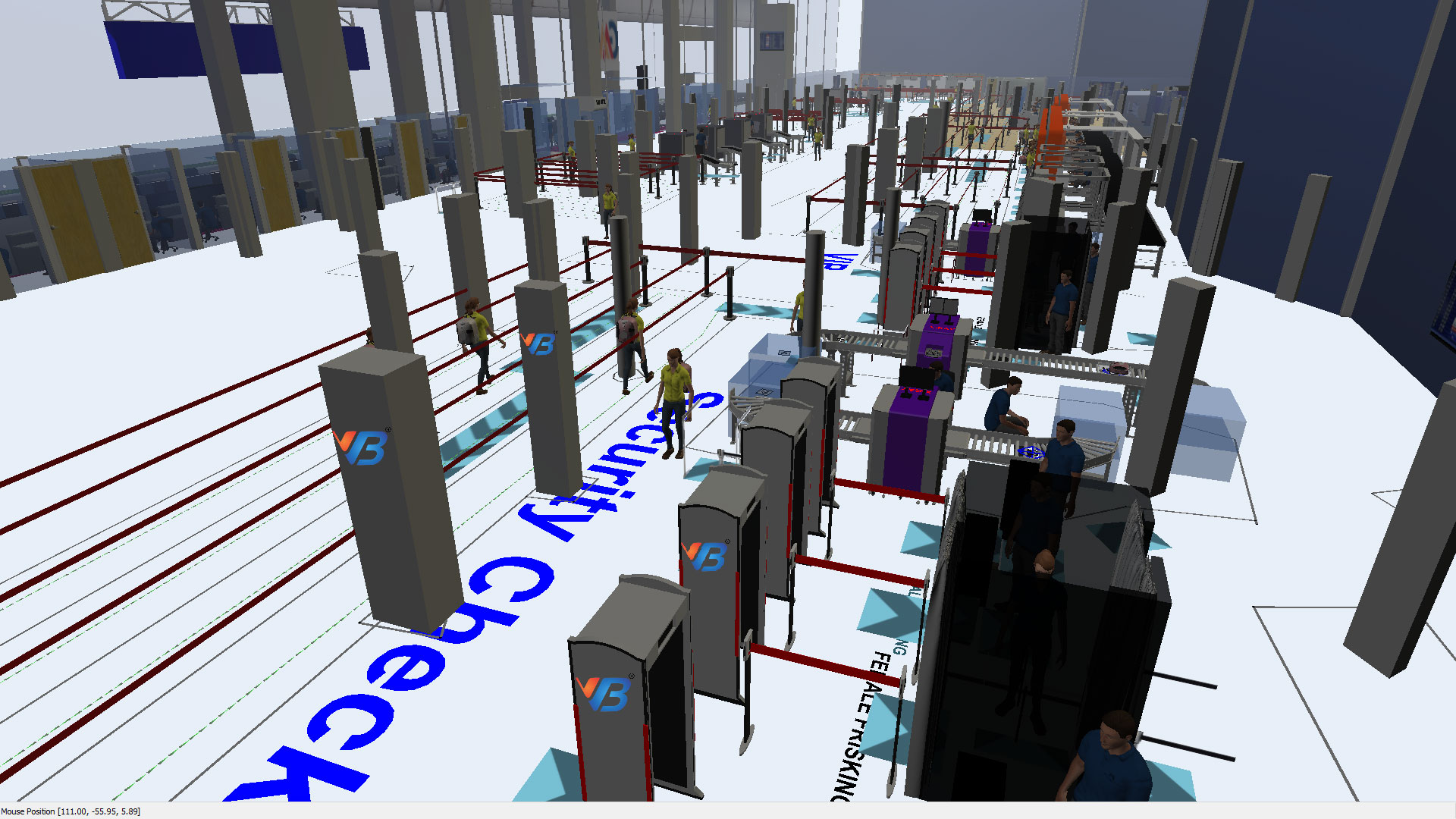

Proximity Requirements:

Constraints on the relative placement, aspect ratio, spacing between and area of the smaller rectangles within a larger rectangle. It Improves the traffic flow and communication among the works. It is for long-term utilization. Architectural floor planning of an office building is a complex task. It involves drafting a building shape, choosing the number of floors, and arranging rooms, stairs, and elevators. The planner must meet some predefined or implicitly understood requirements. In general, the building construction of a flexible building structure In general, the building construction of a flexible building structure compared to the development of a new building is benefit in terms of energy and material costs or rather grey energy with effective rate.

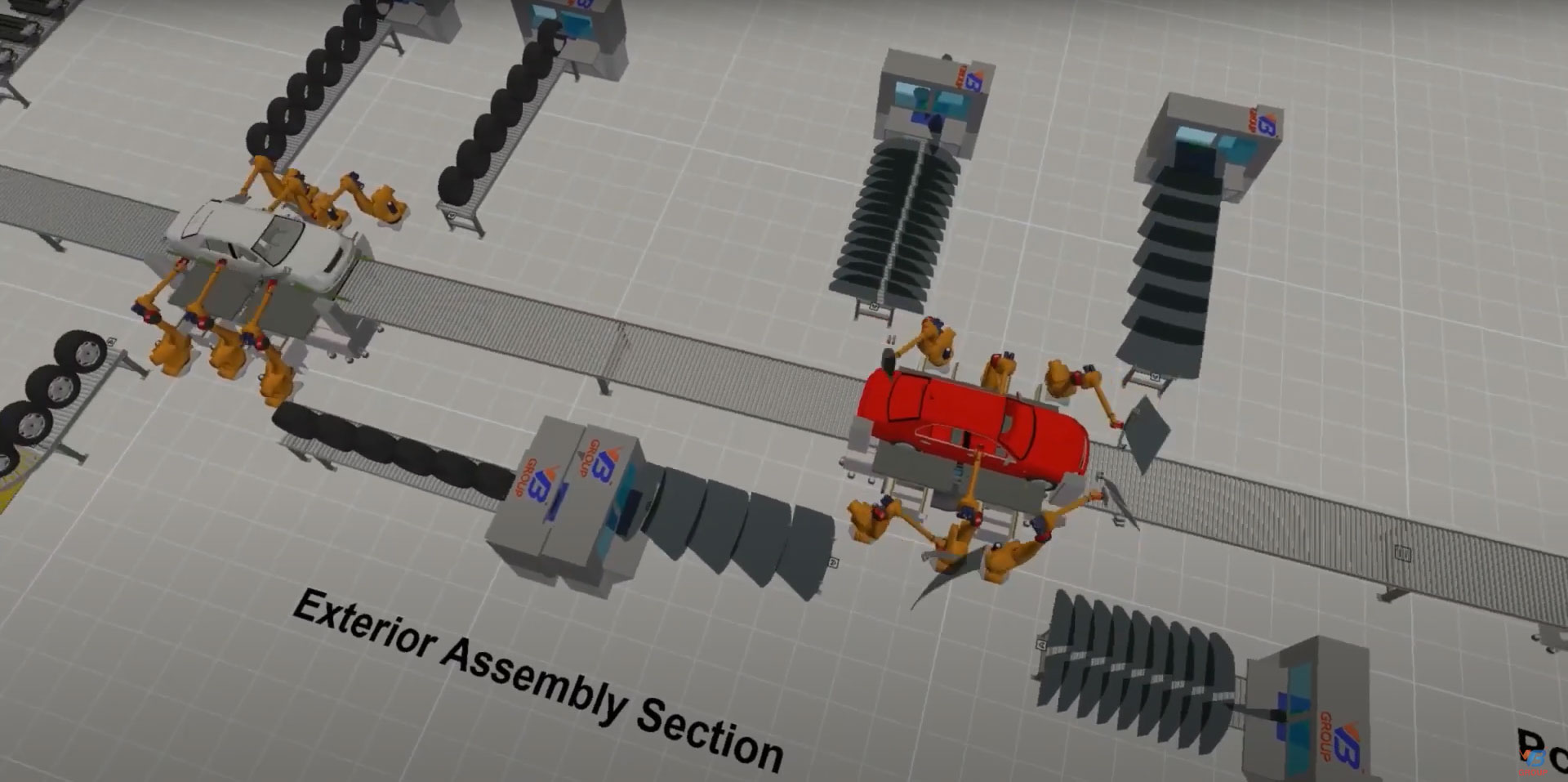

Versatility and Flexibility:

The floor plan should be designed for easy future modifications and adjustments, following a systematic design guideline for flexible industrial buildings that meet the industry 4.0 demands. Flexible floor plans and structures allow for long-term flexibility in use, as buildings can be easily changed to suit different social structures, uses, needs and ideas, which helps create a resilient neighbourhood development. Buildings can be seen and modified as dynamic and adaptable systems that consider the technical and constructive requirements for changing uses during the planning process. Also, the adaptability of space can facilitate self-organised and self-build construction activities, which enhance the acceptance and identification with the building and the neighbourhood.

Lean in Optimal Floor Planning:

Lean in optimal floor planning is a philosophy and a methodology that aims to create more value for customers with less resources and waste. Lean focuses on eliminating any activity or process that does not add value to the customer or the product. Lean also strives to optimize the flow of materials and information, reduce lead times, improve quality, and increase flexibility. Optimal floor planning is the process of designing the best physical arrangement of resources within a facility, such as machines, work centres, desks, etc. Optimal floor planning considers various criteria such as space utilization, material handling, accessibility, safety, etc.

Need more information?

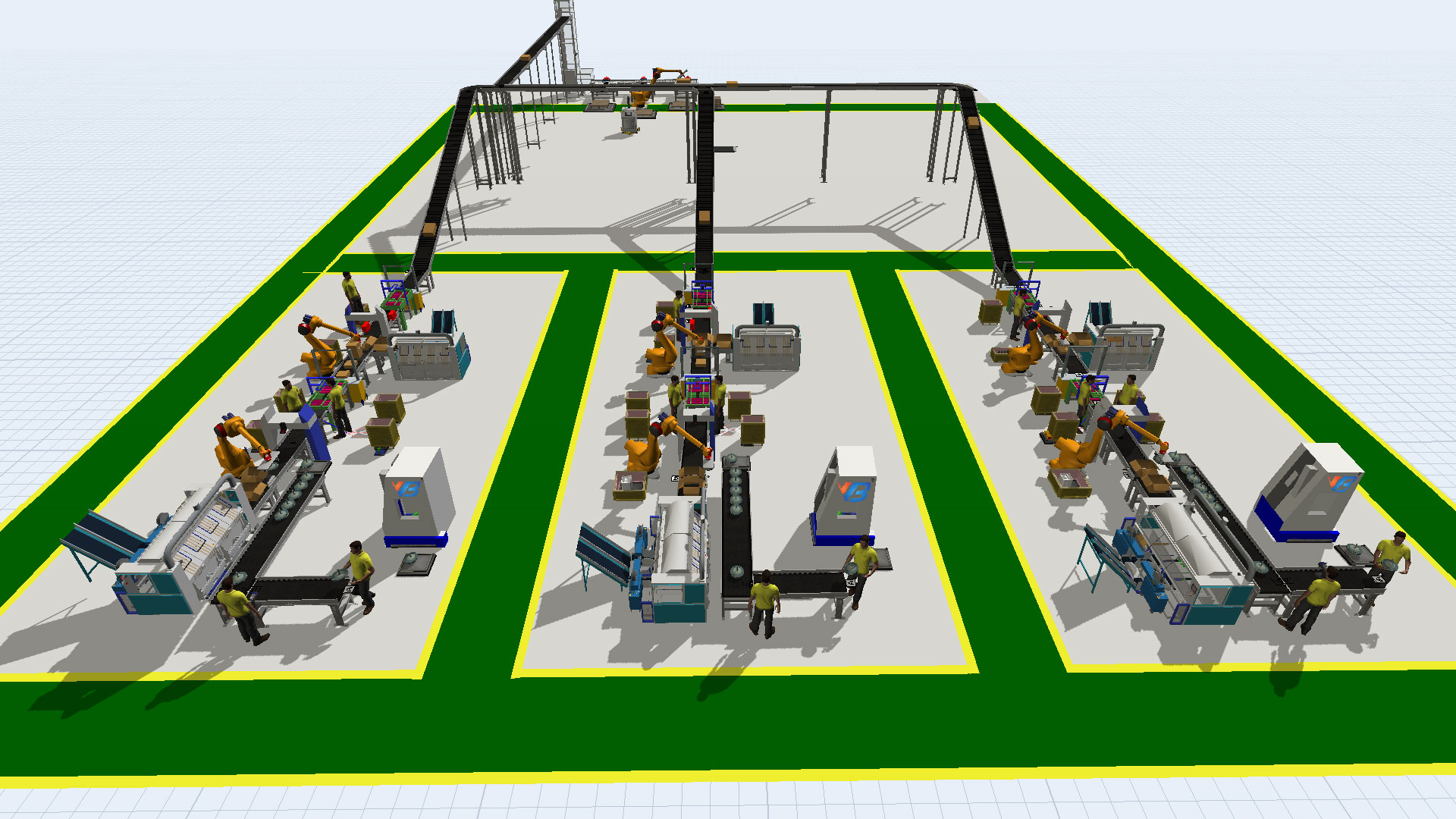

We at VB Engineering provide design and planning services for industries, warehouses, supply chain management systems etc. Design for lean manufacturing is method for applying lean concepts to the design phase of a manufacturing process, supply chain, logistics systems. We at VB engineering use latest technology to apply lean concepts to a system and remove waste like underperforming assets, non profitable machines etc from the system before going to the real time implementation part of it.

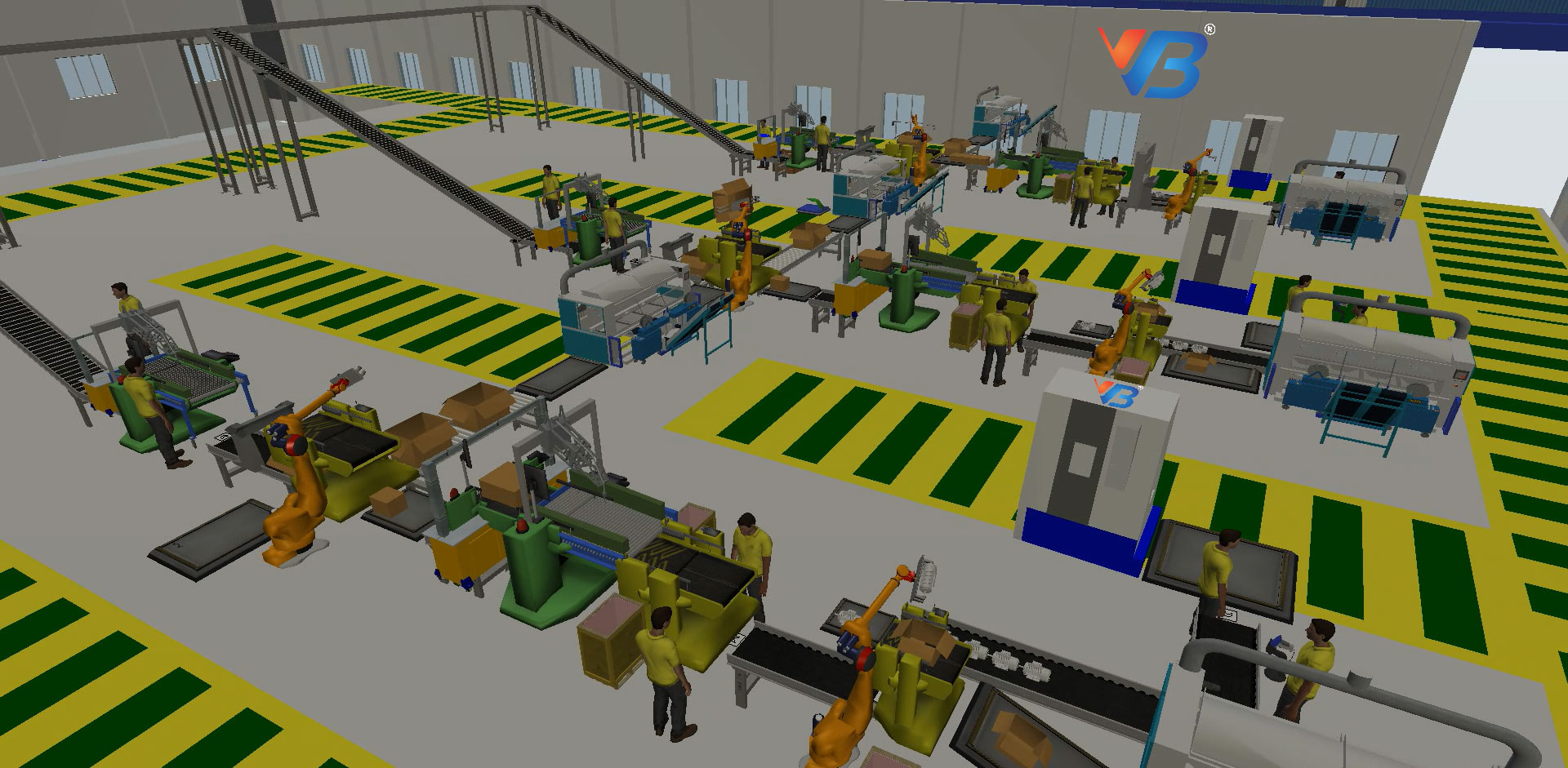

Product-Focused workcells:

For an instant, if a facility must accommodate many new products with short life cycles it must have flexibility for logistics storage and techniques.

Plant-Within-Plant Factories:

Layouts are integral parts of the Lean Manufacturing Strategy. Also Meaningful restructuring requires corresponding physical changes in the layout.

Integrated Support Areas:

These fundamental elements apply to any size facility and at any level. The four layout elements and their variations can produce an almost infinite number of factory layouts.